PRODUCTS-7: OTHER PROCESSINGS

Tungsten Carbide (WC) processing

In comparison with SK or stainless, tungsten carbide (WC) is more expensive and difficult to fabricate.

However, depending on using, it keeps cost low and enable to better product than SK or SUS.

Sometimes we suggest our clients to change their material from others to tungsten carbide.

Many customers have been satisfied that change, so far.

Especially we produce a lot of tungsten carbide drills.

If you are interested in our tungsten carbide products, please let us know.

Below is the main features of tungsten carbide

1. Excel in hardness and abrasion-resistant.

2. No burr.

3. Possible to fabricate high-accuracy product by its rigid substance.

4. Possible to do powder bring from 1 piece.

5. Fewer strain and aged deterioration than other metals.

|

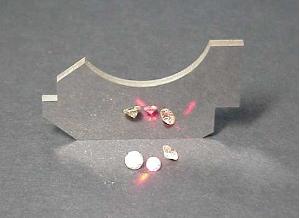

| WC parts |

Prototype products and Technological developments

We support your product development and processing techniques.

We do design development for original machine and jig.

Please do not hesitate to consult us at any time regarding your new products.

Special Material Processing

It’s not just for ceramics, we can provide beryllium copper, vanadium or others,

We can process various special materials for prototype and volume production.

Please ask us whatever you want.

Following chart is part of our examples.

|

|

| ・Single crystal diamond, PCD, and CVD ・Magnet (Neodymium or ferrite) ・Cu-Be (beryllium copper) ・Sapphire ・CBN (cubic boron nitride) ・Brittle materials, ceramic, rare earth and etc. | ・Cutting ・Drum sanding ・Centerless ・Both surfaces polishing ・Drilling ・Inner surface polishing ・Others |

Mirror-Like Finishing

From WC (tungsten carbide), we can process many materials as mirror-like finishing.

Of course, we provide our product with high precision thickness flatness, and parallelism tolerance.

Plus, we can do it for superfine cylindrical pin that is impossible to do by traditional approaches.

DLC Coating

“DLC” stands for Diamond Like Carbon.

It is amorphous conformation and carbon rigid film.

The following four points summarize the most salient features of DLC coating.

1. Abrasion-resistant and low friction

2. Catalyst and anti-adhesion

3. Very thin film thick ness. Average is 1.2 micron meter.

4. If the material has good surface roughness, it has high adhesion.

5. Not good at shock.

6. Difficult to coat on bore diameter (caliber).