The new case has a small window on the top and you can see what kind of knife is inside.

It is very useful to distinguish the knife without opening it.

Plus, we will prepare another color, “white” at the same time.

We are planning that black boxes will be used for room temperature knives and white ones for cryo.

Even if you have many knives on your shelf, you will reduce the time to search for an appropriate knife with this visibility.

Hope you like this window box!

News

As you might know, oriental countries have 12 different zodiac signs that are based in Chinese history.

The animal symbol will be taken over from Snake to Horse in 2026.

If you were born in 1942, ’54, ’66, ’78, ’90, 2002 and ’14, your zodiac is the “Horse!”

Horse is symbolized as “jump”, “advance”, “action”, “challenge” and “passion”.

Some parts of our life are still drifting on a chaotic sea of uncertainty.

You may feel “You can lead a horse to water, but you can’t make it drink.”

But, hold your horses. You may say, the old horse does not forget the way.

Everybody could make the right decision and find the best way, if you try it seriously.

We deeply wish you will have lots of wonderful times next year.

Let’s make a leap forward and higher place!

|

Good news for ultra-thin section researchers! Now the 10.0 mm ultra knife is coming to our regular lineup. We have not only 45-degree, but also 35-degree. |

If you would like to cut wider sections, this knife will be the best option for you for sure.

We have already tried to cut the mouse brain at one of our customers in the USA.

*Section size is 5.5mm(W) x 10.0mm(L) x 80nm(T)

If you are interested in cutting results, can you see the video below?

It will probably be possible to create a wider blade like 12.0mm or more in the future…

Don’t miss our latest news from now on.

We are writing to inform you of a change in leadership within our company.

In October 2025 we have appointed Mr. Yoshio YAMAZAKI as our new president.

We transformed the organization under the new head of company.

We will continue to strive while challenging a new thing.

We provide those items on a “first-come-first-served” basis.

There is a possibility when you ask for a knife, it is already sold out. We are sorry in that case.

Usage |

Model |

Angle |

Width |

Stock Quantity |

| Ultra / Wet | SYM2035 | 35° | 2.0mm (2.0 to 2.2mm) | 5 pieces |

| Ultra / Wet | SYM2045 | 45° | 2.0mm (2.0 to 2.2mm) | 6 pieces |

| Ultra / Wet | SYM3035 | 35° | 3.0mm (3.0 to 3.2mm) | 3 pieces |

| Ultra / Wet | SYM3045 | 45° | 3.0mm (3.0 to 3.2mm) | 10 pieces |

| Ultra / Wet | SYM4035 | 35° | 4.0mm (4.0 to 4.2mm) | 1 piece |

| Ultra / Wet | SYM4045 | 45° | 4.0mm (4.0 to 4.2mm) | 3 pieces |

| Cryo / Dry | SYM2035D | 35° | 2.0mm (2.0 to 2.2mm) | 2 pieces |

| Cryo / Dry | SYM2045D | 45° | 3.0mm (3.0 to 3.2mm) | 4 pieces |

| Cryo / Dry | SYM3035D | 35° | 3.0mm (3.0 to 3.2mm) | 3 pieces |

| Cryo / Dry | SYM3045D | 45° | 3.0mm (3.0 to 3.2mm) | 6 pieces |

| Histo / Wet | SYM3045H | 45° | 3.0mm (3.0 to 3.2mm) | 5 pieces |

| Histo / Wet | SYM3050H | 50° | 3.0mm (3.0 to 3.2mm) | 8 pieces |

| Histo / Wet | SYM6045H | 45° | 6.0mm (6.0 to 6.2mm) | 3 piece |

| Histo / Wet | SYM6050H | 50° | 6.0mm (6.0 to 6.2mm) | 2 pieces |

| Histo / Wet | SYM8045H | 45° | 8.0mm (8.0 to 8.2mm) | 1 piece |

| Histo / Wet | SYM8050H | 50° | 8.0mm (8.0 to 8.2mm) | 2 pieces |

| Histo / Dry (Cryo) | SYM3050HD | 50° | 3.0mm (3.0 to 3.2mm) | 4 pieces |

| Cross-Trim / RT | SYM2545TM | 45° | 2.5mm (2.5 to 2.7mm) | 2 pieces |

| Cross-Trim / RT | SYM2590TM | 90° | 2.5mm (2.5 to 2.7mm) | 4 pieces |

| Cross-Trim / Cryo | SYM2545TMC | 45° | 2.5mm (2.5 to 2.7mm) | 2 pieces |

| Cross-Trim / Cryo | SYM2590TMC | 90° | 2.5mm (2.5 to 2.7mm) | 4 pieces |

| Metalica / 50 | WC50 | 45° | 5.0mm | 6 pieces |

| Metalica / 100 | WC100 | 45° | 10.0mm | 7 pieces |

| Metalica / 200 | WC200 | 45° | 20.0mm | 2 piece |

| Metalica Diago | WC50D | 45° | 5.0mm | 5 pieces |

|

We just exhibited 29th International Conference on High Pressure Science and Technology (AIRAPT-29) in Matsuyama, Japan.

Matsuyama is in the western part of Japan and it is famous for the oldest hot springs and traditional castle on the hill, and various tangerines. We had a booth and displayed various types of our diamond anvils and cells. |

|

|

It is a very good opportunity to introduce our lineups to the people who have never seen or heard about Syntek. Once you use our anvils and cell together, that combination brings you more precise accuracy than the other makers items. It means, you keep making the same experimental condition continuously. Our products are very stable and don’t need many adjustments.We have Almax Boehler type and Perforated Almax anvils, too. If you have special requirements, we will modify anvils and cells whatever you want. This customization is another advantage of our items. |

|

We just exhibited at the National Conference on Electron Microscopy in Wuhan, China. Wuhan is known as a confluence point of 2 big rivers that are Chang Jian and Hanshui. This city has been a key waterway for a long, long time. As you might know this is the biggest Electron Microscopy meeting in China for sure. The event has been held in Dongguan 3 times consecutively. Timing may be good to switch this year to turn over the new leaf. |

|

|

Visitors were interested in Noventa + Cuesta, Quadra, Metalica and Karate Groover. We did a demonstration of Karate Groover in the booth. Many visitors cut glass plates and silicon wafers easily and they were glad of its usefulness and ease. If you have good skills for using microtomes, you don’t need any support features on the knives. On the other hand, if your laboratory has some beginners or immature staff, our knives help them a lot. Time of preparation is one of the key issues for every performance. If you will probably reduce those pre-cutting steps with our Metalica and Karate Groover, you can use your time for productive activities. |

|

We just introduced potential diamond knife users at the 25th Microscopy Conference in Karlsruhe, Germany with our local agent Diapack.

Our booth was not so big, however we had more visitors than we expected. Most of them are coming from Germany, but we talked to many people who live in different countries. We exchanged a lot of information and we got some ideas and tips to create a new knife in the near future. |

|

|

As you might know, we have already released plenty of unique items that the other knife manufacturers don’t make. Even if our existing knives are not suitable for your needs, we will make your own model accordingly. This flexible support is also our big advantage. Of course, the quality of diamonds doesn’t disappoint you. We look forward to seeing you face to face sometime soon! |

We call this knife “Metalica Aqua”.

At this moment, we have only 1 type as Aqua: The blade width is 5.0mm and blade angle is 45-degree.

Aqua has good hydrophilicity. If you try to cut 1um sections, it’s no problem to do.

*See the details of the movie from the link below

As you know, 1um is also available to cut with a Histo knife, however some people don’t want to use a diamond blade due to various reasons.

It’s up to you to use this Aqua. You will probably find a brand new method for cutting by yourself.

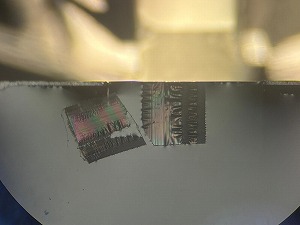

This time, our main product for showing is CVD anvils.

Generally, we have been providing plenty of diamond anvils with natural stones.

On the other hand, we have some requirements that are claiming lower price anvils due to several reasons.

We have already provided CVD bevel anvils for several customers and quality is satisfactory for each one.

Of course, we could make double bevel ones, however we haven’t got any opportunities to use this type at the experiments so far.

We will display the other products, too.

If you have some questions or ideas for your future projects, we are waiting to talk to you at our booth.

Look forward to seeing you in Matsuyama very soon!